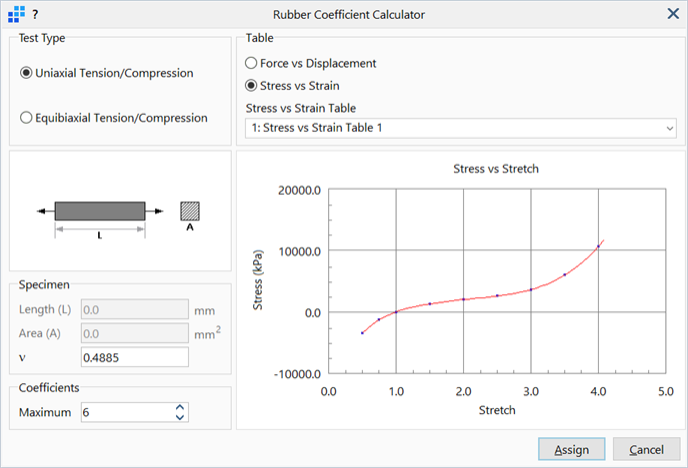

Properties: Rubber Coefficient Calculator

Description

Computes rubber coefficients for the selected rubber material model based on the results of a force vs displacement or stress vs strain test.

Table data is converted to stress vs stretch data and the method of least squares is used to determine the coefficients that produce the curve of best fit through the data.

Dialog

Test Type

Type of test used to determine the stress vs strain or force vs displacement curve.

-

Uniaxial Tension/Compression

Specimen is loaded uniaxially.

-

Equibiaxial Tension/Compression

Specimen is loaded equibiaxially (equal in each of the two axes).

Table

Table used to calculate the coefficients. The table type can be one of the following.

-

Force vs Displacement

Curve is defined by a force vs displacement table.

-

Equibiaxial Tension/Compression

Curve is specified using a stress vs strain table.

Specimen Length (L)

Length of specimen.

Applicable only when table type is Force vs Displacement.

Units are Length (e.g., mm, in).

Specimen Area (A)

Area of specimen.

Applicable only when table type is Force vs Displacement and test type is uniaxial.

Units are Length × Length (e.g., mm2, in2).

Specimen Thickness (t)

Thickness of specimen.

Applicable only when table type is Force vs Displacement and test type is equibiaxial.

Poisson's Ratio

Poisson's ratio of specimen material.

Used only to estimate the bulk modulus for 2D plain strain, axisymmetric and 3D brick rubber properties.

See Materials: Rubber.

Coefficients

Number of coefficients to use when using the Generalised Mooney-Rivlin rubber model.

Must be a number between one and nine.

Warning

A warning will be displayed at the bottom of the dialog if the interpolation produces curves with negative gradients or unstable coefficients.

See Also