Entities: Plate Elements

Description

In Straus7, plate is used as a generic name for a group of two-dimensional or surface elements. These may be used for a range of analysis types including plane stress, plane strain, axisymmetric, plate/shell and 3D membrane analysis.

Element Performance

In terms of accuracy, the ideal shape of a quadrilateral plate element is a flat square. This is not always possible to achieve as elements must be distorted to fit irregular geometries and features of structural members. Distortion of the quadrilateral element can be characterised by warping, skew and aspect ratio. The limit of acceptable distortion depends on the element type and the nature of the stress field. The Straus7 solver issues warnings when element distortion exceeds acceptable limits.

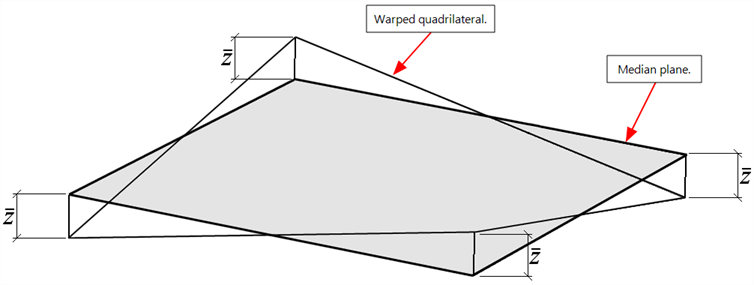

Warping

Shells with curved surfaces can be modelled using a facet approach; that is, modelling the shell with piecewise flat-plate segments. When modelling shells with four-node quadrilateral elements, all four nodes on the element should lie on the same plane. For irregular meshes on these surfaces or a mesh on a general compound curved shell, it may not be possible to achieve this, so the element becomes warped (all nodes not on the same plane).

Considering that any three nodes uniquely define a plane, the element is warped when the fourth node does not lie on the plane defined by the other three nodes. The warping ratio is defined as the ratio of the maximum distance from any node to the median plane, divided by the average edge length. In Straus7, plate element warping ratio may be contoured to check element quality before running the solvers.

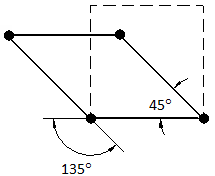

Skew

A quadrilateral element is skewed when one or more internal angles are different from 90 degrees. Distortion of this type is inevitable when modelling structures with irregular geometry or when the mesh is graded.

A practical acceptable range on the internal angles is 45 to 135 degrees for most situations. In Straus7, plate element skew may be checked by contouring the internal angles and the internal angle ratio before running the solvers.

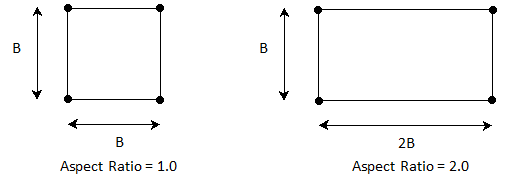

Aspect Ratio

The aspect ratio of a plate is the ratio between its longest edge length and its shortest edge length. A square element has an aspect ratio of 1.0 while a rectangular element has an aspect ratio greater than 1.0 as shown in the figures below.

One of the problems with high aspect ratio elements when used in areas of stress concentration is that they might produce inaccurate results due to the extrapolation of the Gauss point stresses to the corner nodes. On high aspect ratio elements, the extrapolation must be carried out over a longer distance and this, combined with a rapidly changing stress field, means that the element may not capture the stress field accurately.

In Straus7, plate element aspect ratio may be contoured to check element quality before running the solvers.

See Also