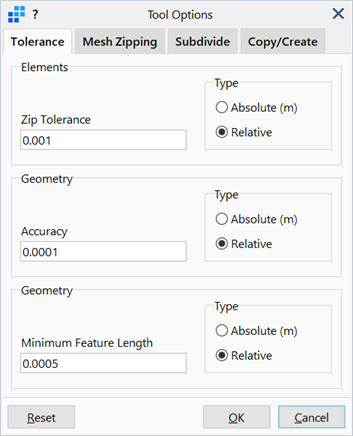

Tool Options: Tolerance Tab

Description

Zip tolerances for background cleaning operations triggered when using tools.

Dialog

Elements Zip Tolerance

Minimum distance between nodes, below which they are zipped together.

Geometry Accuracy

Distance used by the geometry tools to control various internal functions such as edge matching and curve fitting.

For example, a curve is deemed to satisfy the points through which it is intended to pass when the distance between the points and the curve is less than the geometry accuracy.

Geometry Minimum Feature Length

Minimum distance between vertices and edges, below which they are zipped together.

Geometry features (e.g., edge length) smaller than the minimum feature length are usually deleted by the geometry tools.

Geometry Accuracy and Geometry Minimum Feature Length are generally used together. Whilst the minimum feature length is used to select candidates for certain operations (e.g., how close two edges must be before they are zipped and merged together), the accuracy determines how closely the two edges must match after they are merged. The geometry accuracy should always be smaller than the minimum feature length

Type

Method used to define each of the tolerance values above.

-

Absolute

Tolerance is defined in the length units of the model.

-

Relative

Tolerance is defined as a fraction of the nominal size of the model.

Nominal size refers to the largest dimension of a View: Bounding Box that fully encloses the model. The bounding box is parallel to the global Cartesian axes.

See Also