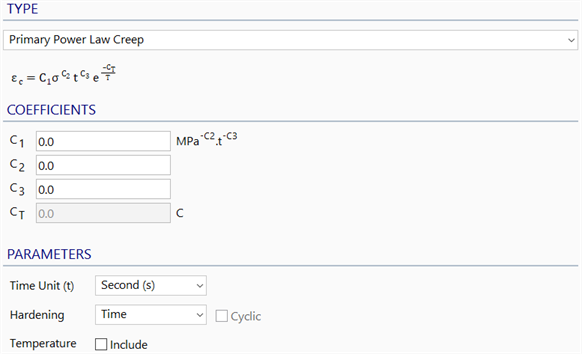

Creep: Primary Power Law Creep

Description

Defines creep data parameters according to the primary power creep law.

The primary power law is the most commonly used creep law for describing first stage metal creep behaviour or primary creep, and involves a function that is parabolic in time. Usually the time index C3 is in the range 0 < C3 < 1. (Note that C3 = 1 corresponds to the secondary power creep law).

Toolbar Functions

See LAYOUTS: Creep.

COEFFICIENTS

C1 is the creep strain coefficient.

C2 is the creep stress index.

C3 is the creep time index.

CT is the creep temperature coefficient.

PARAMETERS

Time Unit (t)

The unit of time in which the coefficients are specified.

Hardening

The creep hardening rule determines whether the creep strain rate is a function of the elapsed time or the amount of creep strain.

-

Time

With this rule, the creep strain rate is calculated based on the elapsed time.

-

Strain

With this rule, the creep strain rate is calculated based on the amount of creep strain in the model. Experimental evidence suggests that the strain hardening rule is to be favoured over the time hardening rule.

If Cyclic is set, extra auxiliary rules are used in conjunction with the strain hardening rule in order to better model stress reversal situations. Such modified strain hardening rule should be used for cyclic loading situations only.

Temperature

This option sets whether the creep law is dependent on temperature or not.

If set, the CT parameter may be specified and the accumulation of creep strain is influenced by the nodal temperatures. The Property Temperature Dependence (see SOLVERS Home: Case Dependence tab) also needs to be assigned in the Quasi-static or Nonlinear Transient Dynamic solver to consider the creep temperature dependence.

If not set, the CT parameter(s) is not used and the creep behaviour is independent of any applied nodal temperatures.

See Also