Metal Creep: Hardening

Description

Time-Hardening

Time hardening assumes that the creep strain rate is a function of stress,

, temperature,

, and time

:

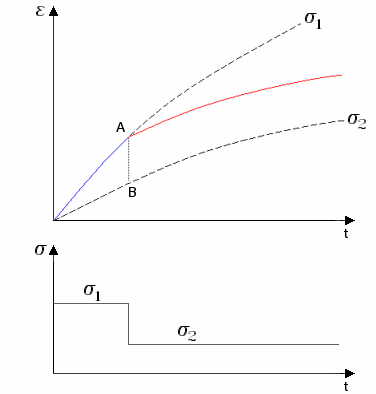

The graph above illustrates the nature of the time hardening model. When the stress level changes from to

the new slope (or creep strain rate) is dependent on the new stress level,

, as well as the elapsed time,

.

Strain-Hardening

Strain hardening assumes that the creep strain rate, , is a function of stress,

, temperature,

, and accumulated creep strain,

:

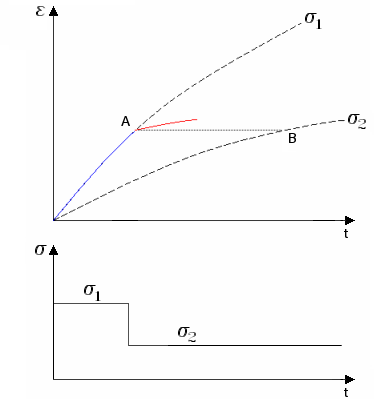

The graph above illustrates the nature of the strain hardening model. When the stress level changes from to

the new slope (or creep strain rate) is dependent on the new stress level,

, as well as the accumulated creep strain,

.

Experimental evidence suggests that strain hardening is to be favoured over time hardening.

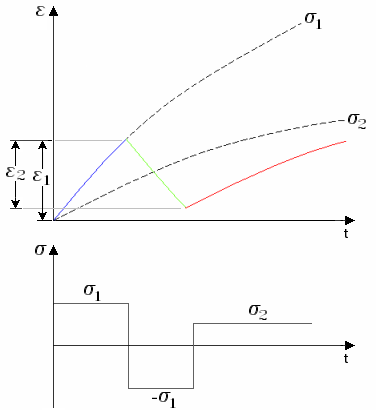

Cyclic-Hardening

Cyclic hardening is a modified version of strain hardening that takes into account the possibility of stress reversals.

For example, if a uniaxial specimen is loaded in tension for a period of time and then is subjected to a compressive load, the strain-hardening that took place in the tensile phase is lost upon changing to compression. The cyclic-hardening option makes use of various auxiliary rules in addition to the strain hardening rule to model this type of situation.

See Also