Special Topics: Using Links in BXS Generator

Description

Links can be used to provide shear compatibility between independent parts of a cross section. For example, in a mirrored section, links can be used to join the two parts to generate a composite section that twists as one, instead of as two independent sections. The composite section will have a higher torsion constant than the sum of two independent sections.

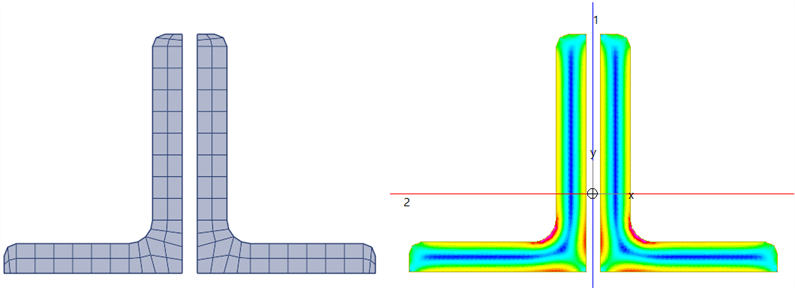

For example, two angles in long-leg back-to-back arrangement without any connection produce a torsion constant, J = 2.347×105 mm4, an area A = 4213 mm2 and the torque stress contour shown below. The two sections act independently in torsion.

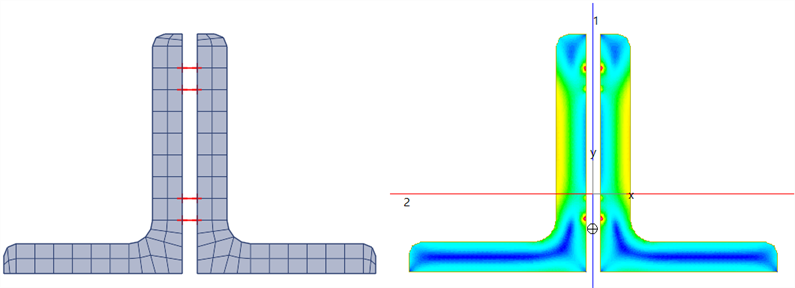

If links are added to represent fasteners, a torsion constant, J = 6.613×105 mm4, an area A = 4213 mm2 and the torque stress contour shown below are obtained. Note that the links provided shear compatibility but did not contribute to the area.

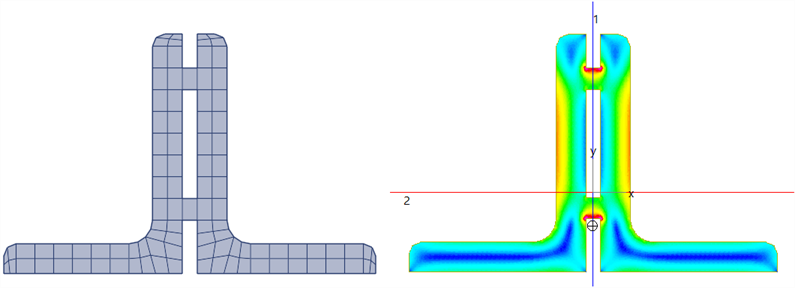

Similarly, if the connection is made using plate elements, a torsion constant, J = 6.540×105 mm4, an area A = 4331 mm2 and the torque stress contour shown below are obtained. The torsion constant is similar to that of the section with links, while the area is slightly higher due to the extra plate elements.

Master-Slave, Pinned, Rigid, Sector and Two-Point links can be used to enforce shear compatibility. All attributes (user-defined coordinate systems, degrees of freedom, etc.) associated with the links are ignored, that is, the link just provides a connection. For example, a Master-Slave link with all degrees of freedom switched off will still be considered to be a connection.

See Also