Results Interpretation: Solver Log File

Description

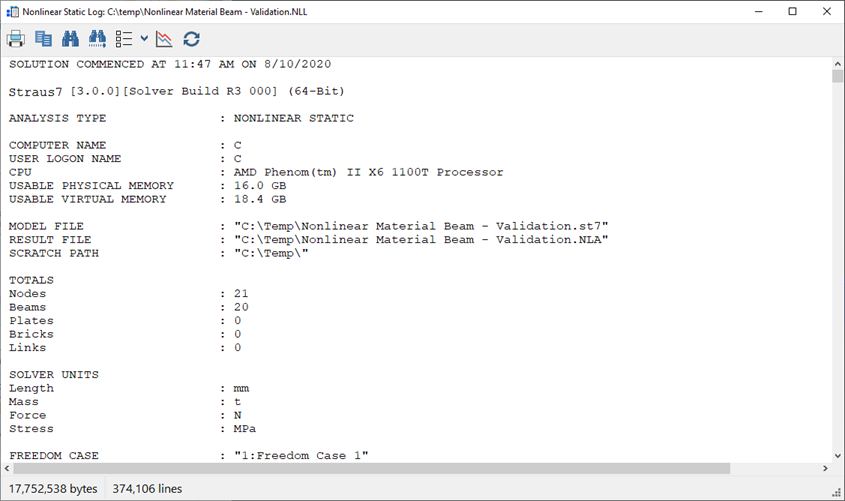

During the solution, messages are printed to the SOLVERS: Solver Window to inform you as to the status of the analysis. These messages may include errors, warnings and notes. All messages printed to the solver window are also stored in a log file (these are files with extensions such as .LSL (linear static log), .NLL (nonlinear static log), .LBL (linear buckling log), etc.). The log file is a text file that should be reviewed in detail at the conclusion of the solution before interpreting the results. The View Log File: Log File Viewer, accessed via Straus7 Menu: View Log File, provides a range of tools and filtering options, and is the best way to view solver log files.

In general, the following checklist can be used:

- Check for note, warning and error messages. The meaning and significance of all such messages should be understood before using the results in any design work.

- Check that the summation of the applied loads equals the intended loads.

- Check the ratio between smallest and largest pivots as this is an indication as to whether numerical ill-conditioning and/or round-off may have affected the results.

Additional Checks for Linear Buckling (.LBL), Natural Frequency (.NFL)

- Ensure that the solution has fully converged to the specified tolerance for all the eigenvalues and eigenvectors of interest. Results will still be provided even though the solution has not fully converged and so the existence of results is not a guarantee of convergence. In the case where full convergence is not achieved, it is likely that at least some of the modes have converged. The modes that have converged can be found from the log file summary, and the results for these modes can be reviewed.

- If the Sturm check was run (recommended), the Sturm check summary in the log file should be checked to ensure that all the eigenvalues have been found.

Additional Checks for Load Influence (.LIL)

- Check that the Virtual Load Cases generated correspond to the requested Response Variables applied in the model.

Additional Checks for Nonlinear Static (.NLL), Quasi-static (.QSL), Nonlinear Transient Dynamic (.NTL)

-

Ensure that the solution has fully converged to the specified tolerances for all load steps. Results will still be provided even though the solution has not converged and so the existence of a result does not necessarily mean that the result is a converged one. In the case where full convergence was not achieved, the results for the unconverged steps should be considered as unreliable. For results which are path dependent (e.g., material nonlinearity is considered), results that follow unconverged results should be reviewed very carefully, even if they are converged.

The results of an unconverged load step are nevertheless very useful for checking the model because they often provide valuable information about why the load step has not converged.

- Note that the Vector Summation of loads printed in the log file will not necessarily equal the sum of the applied loads for the nonlinear solvers. In the first iteration of each load step, the Vector Summation will be equal to the load change between the current and the previous load steps. At subsequent iterations within a load step, the Vector Summation represents the out-of-balance loads in the structure. Therefore, as the increment approaches convergence, this summation tends to zero.

Additional Checks for Harmonic Response (.HRL), Mode Superposition Linear Transient Dynamic (.LTL)

- Check that the listed frequencies and damping ratios are consistent with those calculated in the natural frequency analysis.

- Check that the modal amplitudes and phase angles are correct and appropriate to the physical situation and frequency range.

- If using Rayleigh damping in a mode superposition analysis check that the list of damping factors is consistent with the input data and that the values do not exhibit any significant overshoot or undershoot for transient analysis.

- If using modal damping check that the values of damping listed for each frequency are correct.

Additional Checks for Spectral Response (.SRL)

- Check that the damping ratios are correct and appropriate to the physical situation and frequency range.

- Check that the spectral value for each mode is consistent with the spectral table used.

-

Check that the total mass participation ratio is sufficient (e.g., at least 90%), and that the individual mass participation ratio of each mode is consistent with that mode and the direction of excitation.

Usually, when there are problems with the mass participation, it can be traced to one of the following:

- Too much of the mass is located at or near the supports of the structure.

- A significant proportion of the mass of the structure is concentrated in a few localised, very stiff, areas of the structure. This means that the main mass of the structure does not vibrate except at very high frequencies and will not be excited in a normal mode superposition method that only includes the first few modes. All the lower modes include only a small fraction of the mass.

- In the case of a spectrum that includes a lot of high frequency content, such as for a blast load, many modes may need to be included to ensure that all of the mass is excited by the spectrum. This happens because the higher modes tend to be localised and the associated amplitude and vibration energy is small.

- The structure has many localised modes. Examples include structures where the lowest modes consist of many similar but localised modes in different panels or members.

- Unconverged modes have been included. Unconverged modes can sometimes produce mass participation ratios exceeding 100%. A mass participation ratio equal to 100% is expected when all possible modes are included.

For lateral seismic type loadings of tall slender structures such as buildings, instrumentation racks and the like, the first few modes are almost always characterised by global swaying modes and in such cases problems with the mass participation are rarely encountered. A vertical seismic excitation of these sorts of structures is more difficult. The columns or vertical members in such structures will be very stiff in the axial direction and this means that a very large number of modes, each contributing a small amount, need to be determined. The lack of modes can lead to low mass participation.

Additional Checks for Steady Heat (.SHL), Transient Heat (.THL)

- Check to ensure that the solution has fully converged. If the solution has not fully converged, results will still be available, however these cannot be considered reliable. If a solution fails to converge the reasons for this must be understood and corrected before using the results of the analysis. Viewing the partially converged results may give some clues as to the reasons for the failure to converge.

Log File Composition

Basic information / Preamble

- Date and time when the accompanying results file was created.

- The solver version and analysis type.

- Identification of user, computer and its resources.

- Original path and name of the results file and accompanying log file.

- Total summary of entities in the model.

- Solver units, which is a set of units consistent with the model length unit. That is, the length unit in the log file will be the same as the length unit in the model when it was run, but the other units will be different if the model units were not consistent.

- Summary of solver parameters including convergence tolerance, matrix update, sub-stepping, etc.

Summary of matrix sizes and conditions

- The solver scheme used.

- Total number of equations.

- Matrix fill-in, which is the percentage of non-zero values in the global stiffness matrix after factorisation that were not in the matrix before factorisation.

- [K] matrix size.

- Optimum RAM needed, which is the minimum amount of memory required to enable matrix factorisation to proceed without multiple read passes through the matrix file. If this amount of RAM is not available, the factorisation time is likely to significantly increase.

- Free scratch space, which is the amount of disk space available for writing temporary scratch files.

- Summary of included load and freedom cases.

- Initial conditions.

Body of log

- Load/excitation factors of the current load step, etc.

- Summation of applied loads or virtual loads for included cases.

- Maximum/minimum pivots, which are the largest and smallest diagonal terms of the global stiffness matrix used in the factorisation process. The minimum pivot cannot be zero or even too small because this value is used as a quotient in the factorisation process. If it is zero or too small, it typically indicates a zero or very low stiffness at the reported node and degree of freedom. This can be due to undefined material property data, unrestrained elements, etc. A very small ratio between the minimum and maximum pivots results in a warning message.

- Max translation/rotation increments, which are largest change in displacements and rotations at the reported nodes for the current iteration. If the displacement norm is struggling to converge, check these nodes with high displacement increments to see if there is any modelling mistake or structural instability.

- Largest plate rotation and its plate identification.

- Max residual node force, moment and corresponding nodes. If the force/moment norm is struggling to converge, check these nodes to see if there is any modelling mistake or structural instability.

- Displacement and force/moment norms of the current iteration.

- Relative difference of eigenvalues, or temperature norm change, between current and previous iterations.

- Summary of resulting node displacement and reaction summation.

- Summary of resulting buckling load factors and natural frequency modes.

- Summary of nonlinear beams, contacts, cutoff bars and compression-only support status.

- Summary of mode participation, mass participation ratio and effective modal damping.

- Summary of node and degree of freedom (Node-DoF) used to normalise the eigenvector to produce the engineering modal mass and stiffness values.

- Summary of engineering modal mass and modal stiffness. If a rotational node degree of freedom is used for normalisation, this value will be listed as zero in the translational mode participation table and as non-zero in the rotational mode participation table. If a translational node degree of freedom is used for normalisation, this value will be listed as zero in the rotational mode participation table and as non-zero in the translational mode participation table.

- Kinetic energy of the entire model at each time step of a transient dynamic analysis.

End summary

- Date and time when the solution completed.

- Total CPU time and total solution time.

- Summary of the number of notes, warnings and errors contained in the log file. Note that for a solution restart, this summary refers to the restart, not to all the runs contained in the log file.

See Also