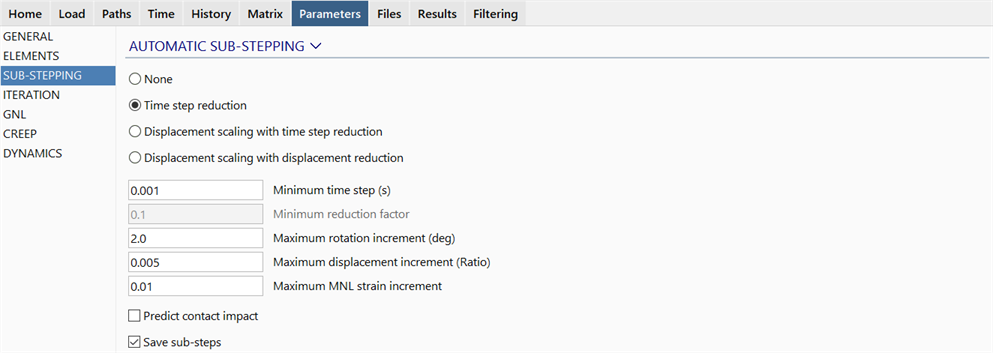

SOLVERS Parameters: SUB-STEPPING (Time Based)

Description

Configures automatic sub-stepping for the Quasi-static and Nonlinear Transient Dynamic solvers.

Automatic sub-stepping is used for improving the convergence of difficult nonlinear models, and/or to reduce the time step to keep the displacement increments from step to step to below a set value.

None

Automatic sub-stepping is not used.

Time step reduction

When sub-stepping is triggered using Time step reduction, the current time step is halved and the step is restarted as a sub-step. That is,

.

If convergence cannot be achieved despite the reduced time step, the time step is halved again and the sub-step is again restarted. The Minimum time step (s) sets the lowest value to which the time step can be reduced.

If a sub-step converges, the time step for the following sub-step is increased towards the full time step defined in SOLVERS: Time Steps. This is calculated as the current time step plus twice the difference between the current and the previous time steps. That is,

.

If this time step exceeds the remaining time in the current step, the time step is set to the remaining time.

The following events trigger a time step reduction in these solvers:

-

The solution does not converge within the set number of iterations and Allow solver to add iterations in SOLVERS Parameters: ITERATION (Structural) is not set.

-

The solution begins to diverge when the set number of iterations has already been exceeded and continuing iteration has been allowed by the Allow solver to add iterations option.

-

The global matrix is singular.

-

The Maximum rotation increment (deg) is exceeded at any node.

-

The Maximum displacement increment (Ratio) is exceeded at any node.

-

The Maximum MNL strain increment is exceeded at any nonlinear material beam.

-

Impending impact between the ends of a Point Contact element (Nonlinear Transient Dynamic solver only).

-

High creep strain rates when creep nonlinearity is considered.

Displacement scaling with time step reduction

In this option, time step reduction is triggered in exactly the same way as for the Time step reduction option, with reductions for non-converging sub-steps continuing until the Minimum time step (s) is reached, if the non-convergence persists.

However, the vector of iterative displacements produced at every iteration of the solution procedure is controlled to avoid large relative movements during the process. This helps to smooth out large load imbalance fluctuations that can sometimes destabilise the iteration process.

The entire vector of displacements and rotations produced in every iteration is scaled down if any node exceeds the Maximum displacement increment (Ratio) or the Maximum rotation increment (deg).

- The Maximum displacement increment (Ratio) is exceeded if any iterative displacement divided by the bounding box dimensions of the model exceeds the set ratio.

- The Maximum rotation increment (deg) is exceeded if any iterative rotation exceeds the set rotation.

In many structures, particularly stiffening structures, the Displacement scaling with load reduction option works very well as it allows the structure to develop the necessary stiffness and stability to eventually equilibrate the total externally applied loads.

Displacement scaling with displacement reduction

This option is similar to the Displacement scaling with time reduction option in that it controls the iterative displacements to ensure that they are no larger than the Maximum displacement increment (Ratio) and Maximum rotation increment (deg) settings.

However, if convergence cannot be achieved within the set number of iterations, or according to the Allow solver to add iterations parameter, the time step is not reduced. Instead, the Maximum displacement increment (Ratio) and Maximum rotation increment (deg) settings are reduced and the sub-step starts again using the same time step. Reductions for non-converging sub-steps can continue until the Minimum reduction factor is reached, but the time step remains the same.

This method is useful in situations where convergence of the majority of time steps does not require an excessively small Maximum displacement increment (Ratio) or Maximum rotation increment (deg). For the time steps that require it, the solver automatically reduces the values.

Parameters

Minimum time step (s)

Specifies the minimum time step allowed during the solution procedure when the step is reduced.

Maximum rotation increment (deg)

Specifies the largest allowable increment of rotation at any node, and is used as described above.

Maximum displacement increment (Ratio)

Specifies the largest allowable increment of displacement at any node as a ratio of the maximum dimension in the structure, and is used as described above.

Maximum MNL strain increment

This is applicable to nonlinear material beam elements only. The fibre strain is monitored and if a strain increment between successive time steps exceeds the set limit, sub-stepping is triggered.

Predict contact impact

Set this option to allow the Nonlinear Transient Dynamic solver to reduce the time step, if necessary, to capture the onset of contact impact. See Time Step Reduction and Point Contacts, below, for more details.

Save sub-steps

If set, saves the sub-steps to the result file.

If not set, sub-stepping may still occur, but the results of the sub-steps are not saved.

Time Step Reduction and Point Contacts

If contacts are present in the model, and time step reduction is allowed together with the Predict contact impact option, Straus7 may reduce the time step to ensure that the onset of contact is captured more accurately. Contact is assumed to occur when:

where:

= current distance between the two nodes on the point contact;

= current velocity of the two nodes, respectively, in the direction of the point contact axis;

= current acceleration of the two nodes, respectively, in the direction of the point contact axis;

= time step for contact to occur.

If the current time step is greater than , the time step is reduced to

, or to the Minimum time step (s) if this is larger than

. This is repeated for each iteration until the current step converges, or the Minimum time step (s) is reached.

Time Step Reduction and Metal Creep

If a Nonlinear Transient Dynamic or Quasi-static analysis considers creep, and time step reduction is allowed, the time step may be reduced to ensure accuracy and/or stability of the solution procedure for the elements undergoing large creep strain rates. An estimate for the time step, , is calculated using the following expression:

where:

= the current effective stress

= the Young's Modulus

= the current creep strain rate calculated using the current stress, time and temperature along with the assigned creep law.

The minimum value of calculated within the model is set as the desired time step.

This method places a restriction on the amount of stress change that can take place over the current time step due to creep to 10% of the current stress levels within the element. is used if it is less than the current user specified time step. However, if

is less than the Minimum time step (s) value, the Minimum time step (s) is used.

See Also