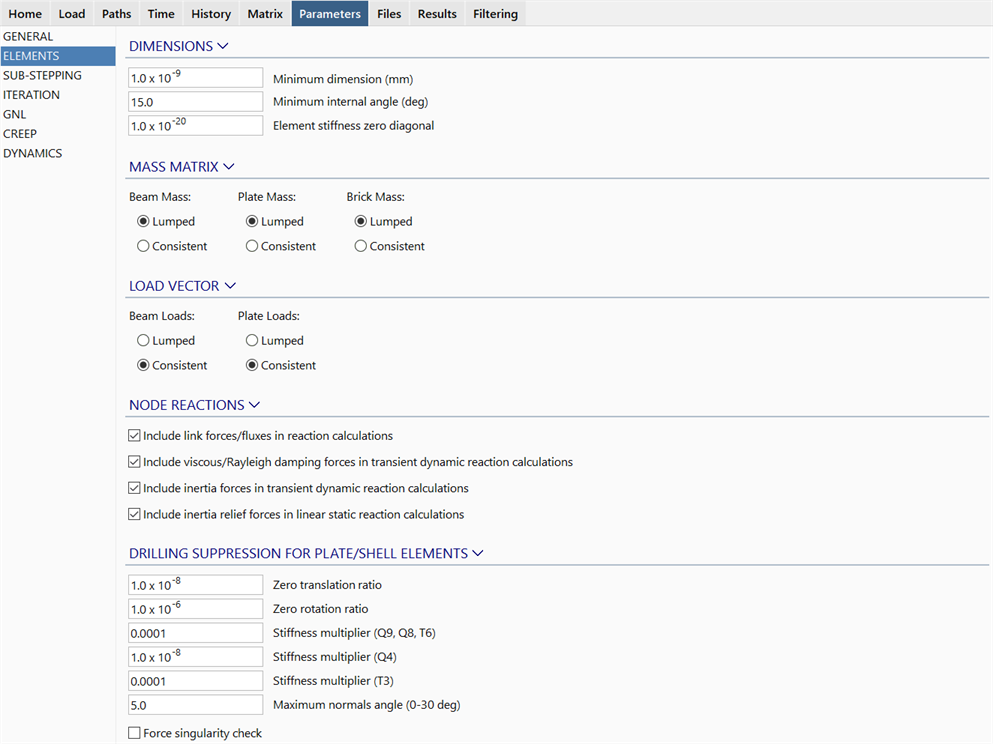

SOLVERS Parameters: ELEMENTS

Description

Configures element-related parameters of the solver.

DIMENSIONS

Minimum dimension

Specifies what is to be considered as zero length for the purpose of identifying collapsed elements.

For example, if two nodes within a plate element are closer than this value, a collapsed plate is assumed and an appropriate warning is given.

Minimum internal angle (deg)

Any plate element that has an internal angle less than the minimum specified generates WARNING[ 73]:Internal angle is out of range in plate xxxx. The setting has no effect on the element assembly, only on the generation of the warning.

Element stiffness zero diagonal

The 4-node isoparametric plate element and the 8-node brick element may include additional internal "bubble" functions to enhance their behaviour and alleviate so called "locking" problems. Straus7 checks the element stiffness matrix during the stiffness matrix condensation (when the bubble degrees of freedom are removed). In the case of diagonal terms less than the specified zero diagonal, ERROR[ 11]:Condensation failure (Plate xxxx) is given for plate elements, and WARNING[ 91]:Condensation has failed for brick xxxx - bubble function not used is given for brick elements.

MASS MATRIX

Beam / Plate / Brick Mass

Sets the type of mass matrix to use for each element type.

-

Lumped

The lumped mass matrix is a diagonal matrix. This approximation generally only includes the effects of translational inertia, or rotational inertia when the principal axes of inertia coincide with the global XYZ system. If this is set but some particular aspect of the model requires off-diagonal terms (e.g., an offset beam or offset plate), the mass matrix is expanded to include the off-diagonal terms for those degrees of freedom that require it.

Analyses using a lumped mass matrix run faster and require less storage space compared with those using a consistent mass matrix. For well refined meshes, the results with a lumped mass matrix are usually comparable to those with a consistent mass matrix.

-

Consistent

The consistent mass matrix is derived by integrating the element's mass matrix in a similar way to which the element's stiffness matrix is integrated. This usually results in a non-diagonal mass matrix. The consistent mass matrix includes the effect of rotational inertia for beams and plates.

Analyses that use a consistent mass matrix may give better results than analysis that uses a the lumped mass matrix, but this is mostly for relatively coarse meshes.

See Entities: Consistent vs Lumped Mass.

LOAD VECTOR

Beam / Plate Loads

Sets the method that converts element loads to an equivalent nodal force/moment vector.

-

Lumped

Transforms loads on elements to equivalent node forces.

-

Consistent

Transforms loads on elements to equivalent forces and moments.

See Entities: Consistent vs Lumped Load.

NODE REACTIONS

Include link forces / fluxes in reaction calculations

If set, forces between nodes connected through links are included in the node reaction calculation. This means that at unrestrained nodes with links attached, the node reactions are reported as zero (or approximately zero due to numerical round-off).

If not set, the forces from the links are not added to the node, and therefore the node reaction reported at unrestrained nodes with links attached, will be equal to the force in the links.

For heat transfer analysis, the reaction is the node flux, and the same procedure applies.

Include viscous damping / Rayleigh damping in transient dynamic reaction calculations

If set, forces due to damping are included in the node reaction calculation. This means that at unrestrained nodes, reported node reaction due to damping is zero.

If not set, forces due to damping are not added to the node, and therefore the node reaction reported at free nodes includes damping forces.

Include inertia forces in transient dynamic reaction calculations

If set, forces due to mass inertia are included in the node reaction calculation. This means that at unrestrained nodes, reported node reaction due to mass inertia is zero.

If not set, forces due to mass inertia are not added to the node, and therefore the node reaction reported at unrestrained nodes includes inertia forces.

Include inertia relief forces in linear static reaction calculations

If set, the applied inertia forces due to the added linear and angular accelerations in inertia relief analysis are included in the node reaction calculation. For a perfect inertia relief analysis, the sum of all applied loads and inertia forces should be zero at every node. This option is typically used to ensure that the inertia relief model is indeed in quasi-static equilibrium with negligible unbalanced loads.

If not set, the added inertia forces to place the model in quasi-static equilibrium are not included in the node reaction results. This option is typically used to check and extract the loads automatically added by the solver to balance the applied loads.

DRILLING SUPPRESSION FOR PLATE/SHELL ELEMENTS

Controls detection and suppression of singularities and drilling degrees of freedom.

To detect nodal singularity and drilling degrees of freedom, the solver extracts two 3×3 sub-matrices from the global stiffness matrix: one sub-matrix for the translational degrees of freedom and another for the rotational degrees of freedom. The rows and columns in each sub-matrix correspond to the stiffness values at the node, defined in the global Cartesian system. For each sub-matrix, the solver calculates the three values and directions of principal stiffness by solving for the eigenvalues (principal stiffness) and corresponding eigenvectors (directions).

To detect and report a stiffness singularity, the following procedure is used.

-

If any diagonal in the translational sub-matrix is less than Zero translation ratio times the maximum principal stiffness of the translational sub-matrix, the node is flagged as having one or more translational singularities.

-

If any diagonal in the rotational sub-matrix is less than Zero rotation ratio times the maximum principal stiffness of the rotational sub-matrix, the node is flagged as having one or more rotational singularities.

To detect and suppress drilling degrees of freedom, the following procedure is used.

-

If only one principal rotational stiffness is less than the Stiffness multiplier times the maximum principal rotational stiffness, the lowest principal stiffness is assumed to be a drilling singularity (i.e., insufficient rotational stiffness about the calculated direction), as long as the node connects only to plate/shell elements. If the drilling singularity is detected, the rotational stiffness in the drilling direction is replaced by a new value equal to the Stiffness multiplier times the maximum principal rotational stiffness.

Maximum normals angle (deg)

Sets the maximum angle between neighbouring 6, 8 and 9 node thick shell elements (Tri6, Quad8 and Quad9) for their surfaces to be considered as continuous and their normals to be averaged.

Firstly, vectors normal to the surface are calculated at the nodes of all thick shell elements. Then, at each node, the maximum angle between those vectors is determined. If the maximum angle so determined is less than the Maximum normals angle, an averaged normal will be used as the normal for all the connected thick shell elements at that node. Otherwise, each element will use its own normal at that node.

This approach is used to achieve a better representation of continuous geometry for a curved shell structure. As the element surface is represented with a quadratic function, continuity of gradient cannot be guaranteed across an element boundary. By sharing a common normal between adjacent elements the effect of geometric discontinuity is reduced.

Force drilling check

If set, unconditionally checks for both translational and rotational degrees of freedom for singularities. Drilling singularities, if they exist, are suppressed while other singularities are simply reported. If Suppress all singularities is set on SOLVERS Parameters: GENERAL, these additional singularities are also suppressed during the matrix factorisation phase.

Note that drilling degrees of freedom are automatically checked when there are Tri6, Quad8 and Quad9 elements in a model and nodes identified as drilling singularities are automatically suppressed.

See Also